While many motorhomes are fitted with a smart set of alloy wheels, not all are and some of these factory wheels can be quite boring and, in the case of older wheels, can really limit your tyre options.

These days, if you’re looking at motorhome upgrades, you will see there are all manner of cool wheel options that can improve the look of your ‘van and personalise it to your preference. Probably the best time to do it is when your motorhome tyres need replacing, because many specialist firms offer deals on wheels and tyres bought together.

Whatever your reason for wanting to upgrade to a new set of alloys, there are a few things to be aware of before you simply bolt the new set on. So let’s get into it!

The basics of wheel sizing

Wheels and tyres are sized in a curious mish-mash of metric and imperial sizes that can be quite bewildering to the uninitiated. Wheel diameters and widths are usually quoted in inches (measured from the inner rim of the wheel – not the outer bit you can see), such as 17-inch diameter and 7-inch wide.

Their bolt pattern is usually four, five or more bolts (or nuts, if studs are fitted) and is commonly quoted in millimetres and referred to as the Pitch Circle Diameter (PCD). The PCD varies between all vehicles and can change from model year to model year on the same vehicle.

The offset (or Einpresstiefe in German – ‘insertion depth’) refers to where the mounting face of the wheel sits, relative to the centreline of the wheel. A wheel with zero offset (ET0) would sit in the exact centre of the wheel, while one with positive offset would sit more inboard. A negative offset wheel will sit further away from the bodywork.

This offset is usually stamped on the reverse of the wheel – often on the spokes – and denoted by ‘ET’ with a number next to it. For example, ‘ET -5’ would indicate a negative offset of 5mm relative to the wheel centreline.

There are usually a range of offsets that will fit your vehicle, but where this can get slightly more complicated is when you change the wheel width or diameter. A wider wheel will always need a different offset from the stock wheel.

Wider wheels also move the tyre to a different position that can cause it to rub on the inner wheelarch, outer wheelarch or suspension components. Any wheel rubbing is an instant MoT failure, because it is safety critical and can cause a tyre to blow-out – not ideal when you want your motorhome to pass its MOT.

Larger diameter wheels also need to be matched with lower-profile tyres so that the overall rolling radius doesn’t change too much (it needs to stay under 3% to ensure that your speedo still reads correctly – while speedo accuracy isn’t part of the MoT, the reading needs to be accurate).

If all this sounds very technical, don’t worry – there are lots of UK-based alloy wheel specialists who know precisely what will fit your motorhome and what will be designed to work with it best. This is another reason for choosing a UK-based or local supplier.

Centre bore

Unless you run a classic Volkswagen campervan, which doesn’t use a centre bore wheel design, then you’ll need to appreciate why the centre bore matters so much. The centre bore

is the hole in the middle of the alloy wheel that fits over the hub of the motorhome. It needs to fit snugly and precisely, because it is responsible for taking all the load running through the wheel.

The centre bore does all the heavy lifting, while the wheel bolts (or nuts) simply clamp the wheel to the centre bore. A wheel that wobbles about on the hub and doesn’t sit correctly on the centre bore is clamped in place by the wheel fixings, and the extra load will cause them to fail. Wheel bolts and nuts are designed primarily to take a tensile load along their thread, not a 90-degree shear load.

Spigot rings

This is the plastic or metal ring that adapts the centre bore of an aftermarket alloy wheel to the hub size of the motorhome. These allow generic alloy wheels to fit a variety of different vehicles by simply varying the offset machining and supplying a different width of spigot rings.

The wheels should never be loose on the hub, and spigot rings are an essential component to ensure correct fitment.

Wheel nuts and bolts

New alloy wheels should come with new wheel bolts or nuts. This is for several reasons. If you have steel wheels fitted, they probably won’t be long enough for the alloy wheels and their shoulder design (often a radius) may not suit the alloy wheel design.

Alloy wheels tend to use thicker material than steel wheels to compensate for the reduced strength, and this usually requires a tapered design of wheel bolt.

There are many different diameters, thread lengths and bolt head designs in use by alloy wheel makers, and these must be mated up correctly with the wheel – radiused heads and taper angles all vary between makers, some use washers, some use flanged bolts and the variation is endless. Happily, you don’t have to worry too much about this – just use the bolts that are supplied with the new wheels (or pay extra to get them, they’re essential).

Original wheel bolts also age and stretch as they’ve probably been on and off the vehicle many times during servicing work and tyre replacement, so it’s essential that they’re not reused on your new set of alloy wheels.

Do not use stainless steel, anodised aluminium or titanium for your wheel nuts or bolts – these are suitable for race cars only.

All wheel bolts and nuts must be torqued up correctly on your vehicle – if you don’t have a torque wrench in your motorhome tool kit, then get a local garage to check them for you.

Too loose and they can come off, too tight and the bolts can snap, so this is an important point. ‘As tight as possible’ isn’t a precise torque value. With new wheels, always re-check the torque settings after about 200 miles.

The curse of the locking wheel nut

Motorhome security will be an important part of looking after your alloys. Unfortunately, thieves also like new shiny alloy wheels, which makes the use of locking wheel bolts or nuts something of a necessity. There are various designs on the market, ranging from McGard models that feature a cookie-cutter shape, tri-pin models, versions with machined slots around their radius and even ones with an actual key built into them.

None of them will protect the wheels from a determined thief, and as most types only use a handful of different patterns, it’s quite easy to buy an entire set of keys online. So they’re more of a deterrent to an opportunist thief than credible protection.

The issue comes with all locking wheel bolts over time. If they’ve been attacked multiple times with a wheel gun at a tyre centre, they wear and become damaged, making them very difficult to remove even with the correct locking key.

We’d recommend replacing them with new items when you fit new alloy wheels and tell all tyre fitters not to use an impact gun (air or electric) on them.

Alloy wheel types

Most alloy wheels are made from cast aluminium, which is simply poured into a mould and then allowed to cool under controlled conditions. Original Equipment wheels are then machined for the bolt pattern PCD and for the offset and centre bore, before being powder-coated or painted.

Aftermarket wheels are made slightly differently in that they’re often a generic wheel pattern that is painted or powder-coated before being machined for centre bore and wheel bolt PCD. This is so that one alloy wheel casting can be fitted to multiple vehicles, but it does also mean that their mounting face is often unprotected from corrosion, and their wheel bolt inserts tend to be plated steel.

There are many different manufacturing methods for alloy wheels, with the most basic being cast aluminium. A step-up from this are flow formed, flow forged or spun forged wheels – they go by lots of different names, but they are all basically cast wheels with spun barrels for strength. They’re tougher and more durable than regular cast wheels.

Split-rims are another popular wheel design, and these feature a separate centre section with either a single barrel (two-piece split-rims) or a front barrel and a rear barrel (three-piece split-rims). This makes them stronger and infinitely customisable for front and rear depth. For a custom look, they’re a great choice. These wheels are often identified by having lots of bolt heads around their rim (though these can be fake bolt heads on some cast wheels to make them look more expensive).

Forged wheels are one of the ultimate wheel types. These are formed from single ingots of aluminium alloy that are heated and crushed into a mould under massive pressure from a forming press. These are the strongest wheels available but the investment on tooling to make them is massive, as 10,000 tonne presses are not cheap!

Motorhome weights also play a part. The essential factor in choosing alloy wheels for a motorhome is to ensure that they are correctly load rated for your vehicle. If you have a 3.5 tonne vehicle, for example, the weight each wheel can support (assuming even weight distribution) would need to be at least 875kg.

In practice, it needs to be far more than this to allow for a safety margin. Take the VW Transporter, one of the best vans for a camper conversion – here, the load rated alloy will typically be rated for around 1000kg.

Tyre know-how

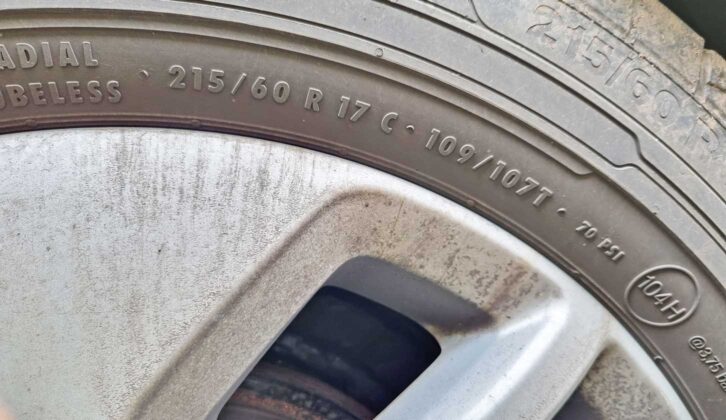

Look on the sidewall of your tyre and you’ll find a confusing list of numbers – for example, 215/60 R17C 109/107T. But what does it all mean? In this case the tyre width is 215mm, the aspect ratio is 60% (meaning that the sidewall height is 60% of the width), R stands for radial (they’re nearly all radial now, so this is a bit outdated), the 17 is the diameter of the wheel in inches, and the C stands for Commercial (meaning it’s a reinforced van tyre). If the tyre was a campervan or motorhome-specific tyre it would be marked CP or Camping.

The 109/107T relates to the load rating of the tyre, the higher the number, the heavier the load it can carry; so in this case the 109 denotes the tyre can carry 1030kg when used on its own and the 107 relates to two tyres being used on a single axle, meaning it can hold 975kg in that orientation. Lastly, the T is the speed rating of the tyre – in this case, 118mph is the maximum rated speed.

In your vehicle handbook, you’ll find a list of common tyre sizes, load and speed ratings, but make sure that any replacement tyres are of speed and load ratings that are identical or higher than those originally supplied on the vehicle. You can’t use lower load rated tyres or lower speed rated tyres because that would risk a blow-out.

Personally, I’d recommend choosing premium brands of tyre – Michelin, Continental, Pirelli, Goodyear and so on – as I believe they are likely to be safer when driving a motorhome in rainy conditions than cheap brands. Even if ‘you never drive very fast or go very far’ you will always encounter an emergency braking situation at some point, and cheap tyres can have far longer stopping distances. Premium tyres tend to wear better than cheap tyres, too, so are often more cost effective in the long-run.

If you have a choice of commercial or camping tyres, always opt for the latter; they’re the better choice, being specifically designed for the needs of a motorhome, as well as being durable and long-lasting.

Also, make sure your tyres are correctly inflated for the weight of the vehicle. As weights in touring trim vary from brochure weights, it’s always wise to check the ‘van’s axle weights on a weighbridge and adjust your motorhome tyre pressures accordingly.

One final point to note – it’s always worth picking the tyre size before you choose the alloy wheel. This may sound odd, but certain tyre sizes are very hard to find – especially smaller sizes for older vehicles (like 14-inch) – so try to pick alloys that use a common tyre size.

Tyres tend to be cheapest online, and websites such as camskill.co.uk specialise in discount tyres – I recently saved a friend £200 on four tyres by mail ordering them, so shop around. Local suppliers can then fit and balance them for around £20-£40 a corner. Don’t forget to also budget for tyre pressure sensors if you have a vehicle with a TPMS – the original sensors may not fit your new wheels and they often corrode in place.

Choose your supplier with care

If you buy wheels directly online – eBay is one of the largest suppliers – then you need to be very careful of the seller. I would personally not buy anything that ships direct from outside the EU, because you can’t always be sure of the quality or if they are correctly load rated and safety tested.

The potential warning signs for new wheels are if they are very cheap and shipped direct from overseas. While some may be perfectly reputable, it’s a lucky dip of quality and many are simply badly copied products.

If you order wheels online and they don’t fit, or are not of good quality, then you have limited return options. Most require the wheels to be returned to the maker, but re-sending them back to their country of origin can be more costly than the wheels themselves.

and takes up to 1150kg in weight

We’d highly recommend only buying from a UK firm that advertises in the magazine, or from a show or local supplier. These sellers are all subject to UK warranty and quality requirements, as well as being bound by the Consumer Rights Act in the event of any issues.

There are lots of great UK-based wheel suppliers that sell high-quality wheels, too.

Used wheels can be fine, so long as you carefully check them for straightness, cracks, buckles and corrosion. Certain types of damage can be sorted out by a professional alloy wheel repair firm, but large cracks or chunks of material missing often can’t be repaired.

Split-rim designs can also be problematic, and because they need all the bolts replacing during the refurbishment process, they typically cost around three times the price of cast wheels to refurbish. Do not buy any split-rim wheels where the bolt heads have been painted over or powder-coated – that is potentially a sign of a bodge.

We’d look for manufacturer ‘take offs’ which are often for sale at alloy wheel shops that take them in part exchange when customers want to upgrade their wheels.

Can you use car wheels on a motorhome?

One of the cheapest options that we’ve seen on many ’vans is to simply fit a set of car wheels with the same bolt pattern. But just because the wheels physically bolt on doesn’t mean you should do so. The centre bore may be different – causing the bolts to stretch or fail – and they won’t be rated for the weight of a ’van or motorhome.

This increases the chances of them buckling over a pothole or cracking or snapping in service. Car tyres should never be used on motorhomes – they do not have as many plies in the sidewall and can’t support the weight.

Cleaning your motorhome wheels

It’s tempting to use your local car wash to clean your vehicle, and hundreds of these super cheap and fast car wash centres have sprung up across the UK in the last few years. You have to be a little bit careful here, because some of the products that are used on the wheels can be acid-based and can damage the finish of alloy wheels.

Alloys will either be painted, powder-coated, anodised, diamond cut and lacquered or simply polished. Bare polished wheels and diamond-cut wheels are very susceptible to acidic cleaners and must be cleaned following the manufacturer’s instructions (usually they just say use a mild car wash soap and warm water).

Do not use washing-up liquid on wheels or bodywork – it’s far too powerful a degreaser and can easily damage finishes.

It’s best to clean alloy wheels as soon as they become heavily covered in brake dust, because the metallic particles in the pad material can eat into the finish and can cause permanent damage.

While wheels can be a pain to clean by hand – especially the more intricate designs – the good news is that you don’t have to worry about this, because there are now lots of good non-acidic cleaners on the market to make the job a lot easier.

The budget option is something like Redline wheel cleaner, which is available for around £15 for two bottles with trigger sprays and turns a shade of purple when it is time to rinse it off.

I think the best option – which has won many magazine awards – is Bilt Hamber Auto-Wheel: it’s a non-acidic and non-alkaline cleaner that you simply spray on the wheels and wait until it changes colour (it also goes a fetching purple) before jet washing it off. It is very effective and saves all the tedious mucking about with small brushes or sponges on your knees. It costs about £16 a litre, but they also offer a five-litre tub (which you can then decant into a plant sprayer) for around £60. It’s the best one I’ve tested and is highly recommended.

Some people also choose to ceramic coat their wheels as a preventative step, and there are many products all claiming various wonderful things. But the key thing is to stay on top of cleaning your alloys to keep them looking their best.

Don’t miss our guide on how to clean a motorhome either, if you want to explain how to keep the whole of your ‘van looking its best.

Inform your insurer

Make sure you tell your insurance company if you’re changing the wheels on your vehicle. Most will simply add them on for a modest alteration fee, but high-value wheels may increase the premium slightly. But it won’t be by much and it’s a legal requirement to inform them.

You do need to tell them because otherwise they might not be covered for theft, and may invalidate or reduce the value of a claim in the event of an accident. As with all modifications, it’s important to let them know them – not doing so isn’t a wise move.

The same goes for remaps (insurance assessors routinely plug into the diagnostics port of vehicles to get the crash data these days).

A few UK Alloy Wheel Manufacturers

- Image Wheels, West Midlands

- 3SDM Wheels, South of England

- Discount online tyre supplier camskill.co.uk

Future Publishing Limited, the publisher of Practical Motorhome, provides the information in this article in good faith and makes no representation as to its completeness or accuracy. Individuals carrying out the instructions do so at their own risk and must exercise their independent judgement in determining the appropriateness of the advice to their circumstances. Individuals should take appropriate safety precautions and be aware of the risk of electrocution when dealing with electrical products. To the fullest extent permitted by law, neither Future nor its employees or agents shall have any liability in connection with the use of this information. Double check any warranty is not affected before proceeding.

If you’ve enjoyed reading this article, why not get the latest news, reviews and features delivered direct to your door or inbox every month. Take advantage of our brilliant Practical Motorhome magazine SUBSCRIBERS’ OFFER and SIGN UP TO OUR NEWSLETTER for regular weekly updates on all things motorhome related.

Leave a Reply